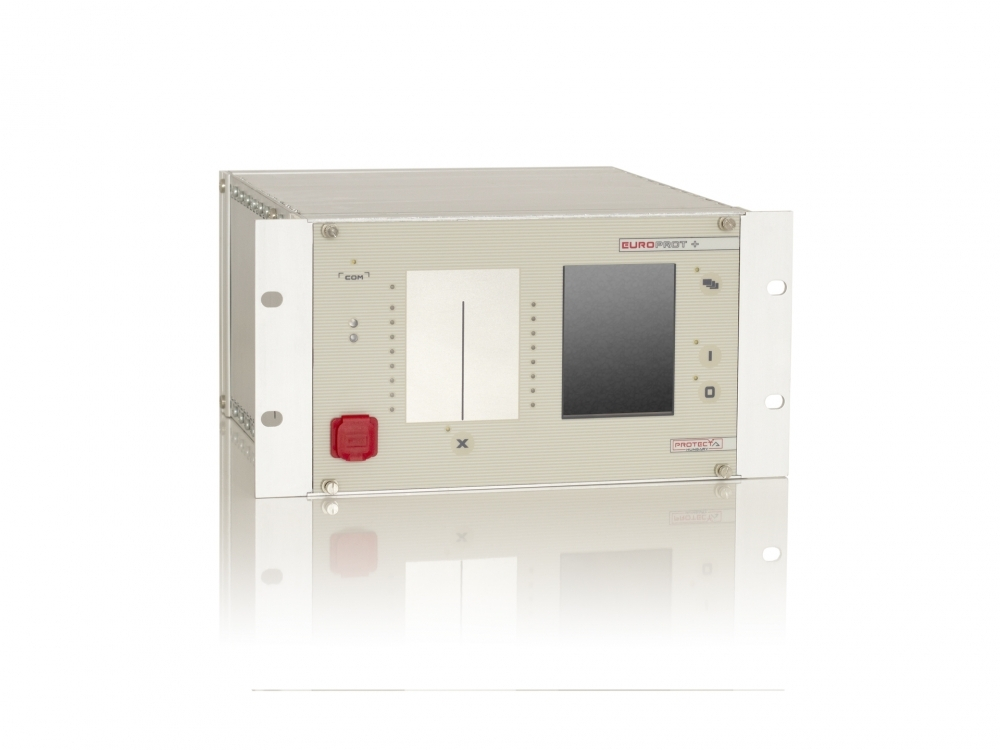

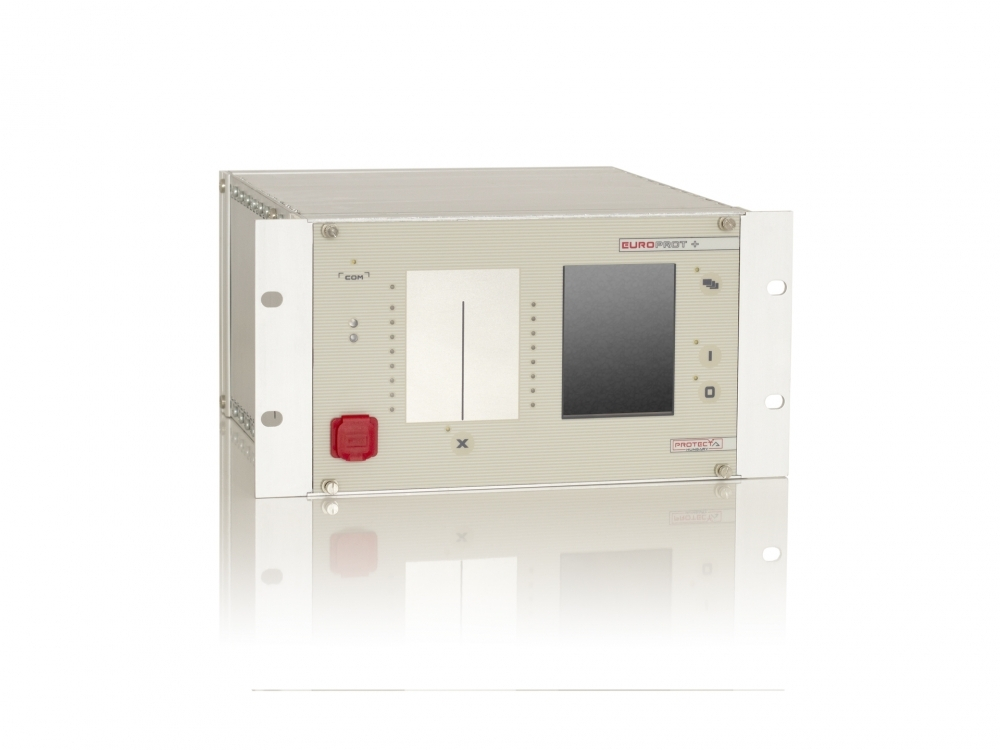

The E7-Feeder is a dedicated motor protection and control IED; it is member of the DTIVA product type in the EuroProt+ product family.

The DTIVA products are configured to protect, control and supervise elements of the utility and industrial distribution systems. Because of the modular architecture, the modules are assembled and configured according to the user’s requirements; from that point on, the software determines the functions.

The EuroCAP configuration tool, which is available free of charge, offers a user-friendly and flexible application for protection, control and measurement functions to ensure that the IED-EP+ devices are fully customisable.

General features

- Native IEC 61850 IED with Edition 2 compatibility

- Scalable hardware to adapt to different applications

- 84 HP or 42HP wide rack size (height: 3U)

- The pre-defined factory configuration can be customized to the user’s specification with the powerful EuroCAP tool

- Flexible protection and control functionality to meet special customer requirements

- Advanced HMI functionality via color touchscreen and embedded WEB server, extended measuring, control and monitoring functions

- User configurable LCD user screens, which can display SLDs (Single Line Diagrams) with switchgear position indication and control as well as measuring values and several types of controllable objects.

- Various protection setting groups available

- Enhanced breaker monitoring and control

- High capacity disturbance recorder (DRE) and event logging:

- DRE for up to 32 analogue and 64 digital signal channels.

- Event recorder can store more than 10,000 events.

- Several mounting methods: Rack; Flush mounting; Semi-flush mounting; Wall mounting; Wall-mounting with terminals; Flush mounting with IP54 rated cover.

- Wide range of communication protocols:

- Ethernet-based communication: IEC61850; IEC60870-5-104; DNP3.0 TCP; Modbus TCP

- Serial communication: DNP3.0; IEC60870-5-101/103; MODBUS, SPA

- The EuroProt+ family can handle several communication protocols simultaneously.

- Built-in self-monitoring to detect internal hardware or software errors

- Different time sources available: NTP server; Minute pulse; Legacy protocol master; IRIG-B000 or IRIG-B12X

The E7-Feeder configuration is designed to protect, control and supervise medium- to large-sized three-phase motors in the manufacturing and processing industries. The IED provides a wide range of protection functions, which are based on current, voltage and temperature measurements: non-directional overcurrent, directional earth fault protection, various voltage protection functions (over-/undervoltage, negative, positive sequence, residual voltage protection),

In addition to these basic functions, the relay provides a number of other special motor protection and supervision functions that enable it to protect and run the motor more effectively and safely: motor thermal protection, motor startup supervision, asymmetry protection, loss of load protection, prolonged start locked rotor protection.

The motor differential protection function is available as an option in the E7-Feeder relay.

The relay can record the starting current, which is most helpful in analysing motor performance during the critical start-up period.

Furthermore, the relay offers control, measuring and monitoring functions; consequently, the IED can be used as a bay control device.

Scope of application

- Protect motors in industrial networks and power plants

- Protection against thermal overload of the stator and rotor

- Monitoring the thermal state of the motor by motor thermal replica function

- Voltage transformer supervision

- Phase reversal protection with negative sequence overvoltage protection

- Motor start-up supervision

- Overload detection while in use

- Temperature monitoring via temperature sensors with RTD module

- Loss-of-load (undercurrent) protection

- Protection against instability due to undervoltage

- Differential protection for internal phase-to-phase or phase-to-ground faults

- Back-up protection unit application

The E7-Feeder configuration is designed to protect large motors on the medium-voltage network. It measures three phase currents, the residual current and, additionally, three phase voltages and the residual voltage. These measurements facilitate the operation of current- and voltage-based functions.

In addition to the usual overcurrent and overvoltage functions, this configuration includes special motor protection functions such as a dedicated thermal replica function for motors, negative sequence overcurrent protection function, asymmetry protection, loss of load protection, motor startup supervision. Alternatively, the E7-Feeder unit may be applied as a differential protection together with the optional motor differential protection.

| IEC61850 documents | version | Format | Date | Size |

|---|---|---|---|---|

| TISSUEs Implementation Conformance Statement (TICS) for the IEC 61850 Edition 2 server interface in Europrot+ product family | 1.0 | 18/04/2023 | 569.01 KB | |

| Protocol Implementation eXtra Information for Testing (PIXIT) for the IEC 61850 Edition 2 server interface in Europrot+ product family | 1.03 | 18/04/2023 | 555.52 KB | |

| Protocol Implementation Conformance Statement (PICS) for the IEC 61850 Edition 2 server interface in Europrot+ product family | 1.02 | 18/04/2023 | 478.52 KB | |

| Model Implementation Conformance Statement (MICS) for the IEC 61850 Edition 2 server interface in DTIVA product | 1.0 | 18/04/2023 | 391.88 KB | |

| Protocol Implementation Conformance Statement (PICS) for the IEC 61850 Edition 1 server interface in Eurorot+ product family | 1.1 | 20/03/2017 | 261.09 KB | |

| Protocol Implementation eXtra Information for Testing (PIXIT) for the IEC 61850 Edition 1 server interface in Europrot+ product family | 1.1 | 20/03/2017 | 259.27 KB | |

| Model Implementation Conformance Statement (MICS) for the IEC 61850 Edition 1 server interface in the Eurorot+ product family | 1.0 | 21/05/2012 | 864.71 KB | |

| Type description | version | Format | Date | Size |

| Distributed network components protection & control | 1.2 | 18/07/2025 | 3.22 MB | |

| Hardware Guides | version | Format | Date | Size |

| Hardware description | 2.21 | 05/05/2025 | 5.48 MB | |

| Maintenance guide | 2.1 | 28/06/2023 | 770.85 KB | |

| Application Guides | version | Format | Date | Size |

| Operating Manual and Troubleshooting Guide - system version: 2.8 | 1.5 | 19/09/2023 | 2.69 MB | |

| Configuration Descriptions | version | Format | Date | Size |

| E7-Feeder configuration description | 2.2 | 25/07/2016 | 1.95 MB | |

| E7-Feeder_H product configuration options | 5.3 |

01/10/2025

|

- | |

| E7-Feeder_F product configuration options | 5.2 |

01/10/2025

|

- |

Please always refer to a valid Order Code when placing an order.

The Order Code page can be opened by clicking the link below.

| E7-FEEDER_H: |  |

E7-FEEDER_F: |

|